Model No.: XF980X1200 Composite Sandwich Panel Machine

Brand: XF

Material Of Rollers: 45# Steel

Certification: ISO

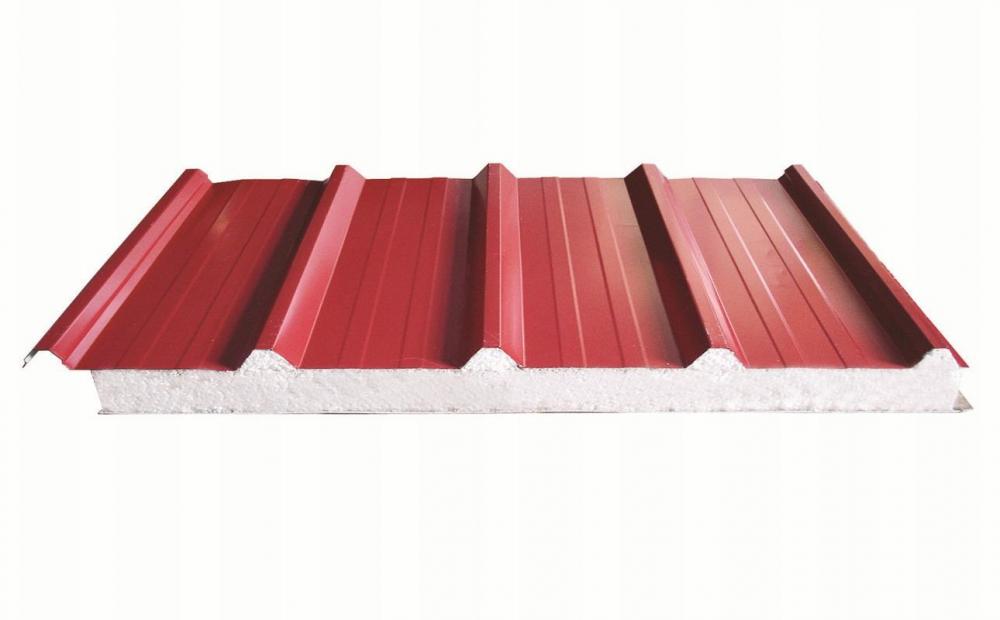

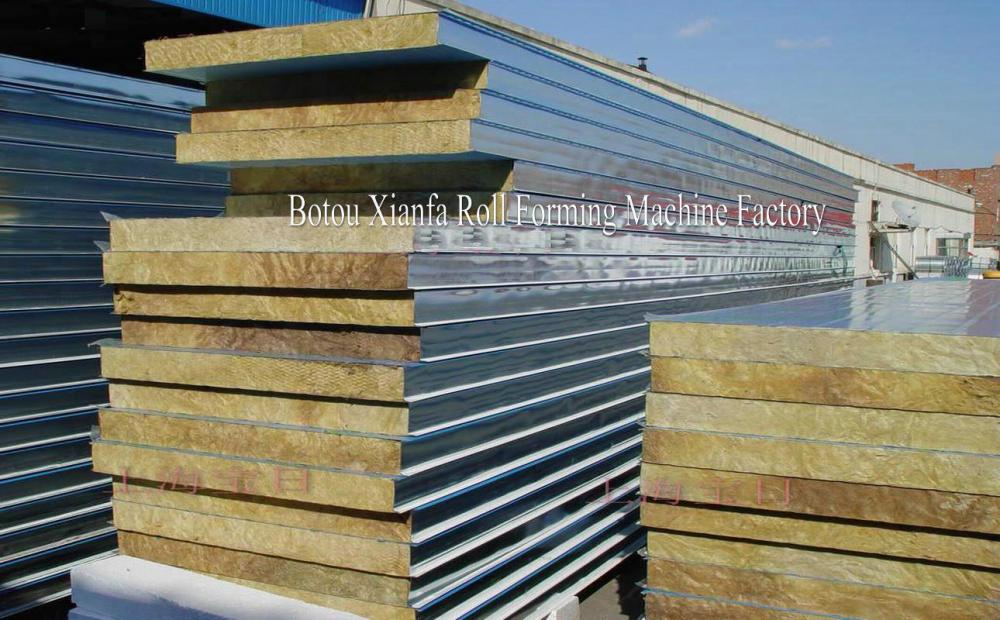

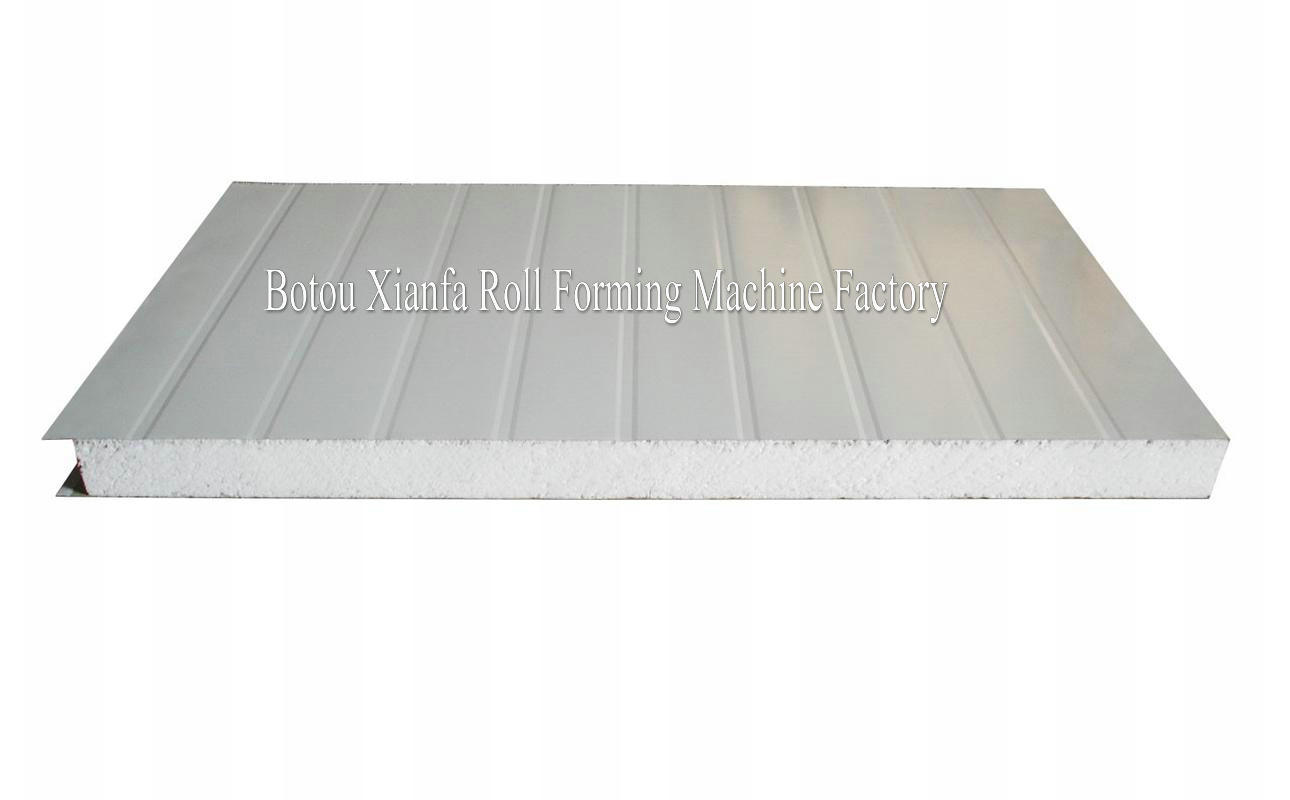

Usage: Wall

Tile Type: Colored Steel

Condition: New

Customized: Customized

Transmission Method: Hydraulic Pressure

Control System: PLC Control

Voltage: 380V 50Hz 3Phases

Machine Name: Composite Sandwich Panel Machine

Name: Aluminum Composite Sandwich Panel Machine

Machine Type: Hydraulic Composite Sandwich Panel Machine

Packaging: We have professional technicians for loading Guaranteed the goods load into container without any damage.

Productivity: 30set

Transportation: Ocean,Land

Place of Origin: Botou City China

Supply Ability: 30

Certificate: CE/ISO

HS Code: 8455221000

Port: Tianjin New Port

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF

Hydraulic Aluminum Composite Sandwich Panel Machine

Cladding Sheet Roll Forming Machine,Aluminum Sandwich Panel Machine,Composite Wall Panel Machine

Composite Sandwich Panel Machine Equipment Detailed Parameters

| No | Forming Machine Parameter | |

| 1

| Suitable Material | Colored Steel plate, Galvanized board |

| 2

| Width of the raw material | 1000/1200mm |

| 3 | Total Power | 28KW |

| 4 | Thickness of raw material | 0.3-0.7mm |

| 5 | Thickness of Panel | 50-200mm |

| 6 | Machine Length | 23500x2440x2450mm |

| 7 | Weight | 9600KG |

| 7 | Speed | 0-4m/min |

| 8

| Voltage | 380V 50Hz 3phases |

Composite Sandwich Panel Machine Machine Component

| Decoiler 1 It adopts coil holder with break device. 2 Loading capacity: Less than 6T 3 Width: 1200mm Roll Forming Machine 1 Main Frame: 300 H steel welding 2 Main Board:14mm 3 Shaft diameter:70mm 4 Roller Station:15row(Roller material 45# steel,roller surfaces polishing, hard plating) 5 transmission way: chain draive 6 Power:3KW 7 Feeding Device has pre-cutter 8 Size::7260X2050X670mm 9 Weight:About 3T Composite Part 1 This part including: Press rib, glue, heating, combine, slotting, ending and pneumatic move up and down. 2 Main machine adopts frequency conversion 3 Thickness adjustable by electric 4 Shaft of combine shaft:150mm, material is steel with rubber cover,to avoid any wear 5 Foam machine has 18 roller shaft, Rib rollers 6 rows 6 Transmission Way:Transmission and chain drive 7 :Reduction box power: Foam machine 3KW,with reduction box. 8 Main frame adopts square tube welding ,to make sure machine is stable and work smoothly Size:11.5X2.3X2.5m Electric system 1 Control: DELIXI low-voltage apparatus 2 Specification :programmable PLC and Delta PLC, double calculator, to insure the length 3 7inch touch screen ,failure warning Cutting Part 1 Non stop cutting , Pre-cutter can cut the length automatically 2 Pneumatic pressing device, control the cutter. And back to revious after cutting. 3 Cutting method: saw and cutter 4 Power:4KW 5 Size:1750X2520X1850mm 6 Weight:700KG. Feeding material of composite and roll forming part:1200mm Stacking Part 1 It adopts angle iron and square tube 2 Every stacker has 4 roller 3 Size; 3X1.3X0.8m 4 holding hook 1 piece, uncoiler core: 4 pieces, uncoiler holding part: 1 piece. |

Components of production line

| No. | set | Name | No. | Set | Name |

| 1 | 1 | Uncoiler | 15 | 2 | remain glue reciver |

| 2 | 1 | Main composite machine | 16 | 4 | Uncoiler core |

| 3 | 2 | 17 | 1 | φ250milling cutter | |

| 4 | 2 | Transport table | 18 | 18 | Adjusting block |

| 5 | 1 | Roll forming machine | 19 | 25m | Plastic foam |

| 6 | 1 | foam holder | 20 | 20m | Bubble wrap |

| 7 | 4 | Holder pipe | 21 | 1 | Pipe tip |

| 8 | 1 | coil uncoiler | 22 | 1 | seal gum |

| 9 | 1 | ladder fence | 23 | 2 | chuck |

| 10 | 1 | coil hook | 24 | 2 | filter screen |

| 11 | 6 | dropper | 25 | 2m | sponge |

| 12 | 3 | Branking vane | 26 | 1 | Fluorescent tube |

| 13 | 6 | hopper | 27 | 6 | Infrared ray heating tube |

| 14 | 4 | Glue brush |

|

|

|

Why Choose Botou Xianfa Roll Forming Machine Factory

1) Q: Do you have after sales support?

A: Yes, we are happy to give advice and we also have skilled technicians available across the world

We need your machines running in order to keep your business running.

2)Q: How do your machines compare with other big companies in this market?

A: We are up to date with the latest technology and improve our machines accordingly

3) Q: Will you deliver the right goods as ordered? How can I trust you?

A: Yes, we will. The core of our company culture is honesty and credit

Xianfa is ALIBAB`s Gold supplier with BV assessment and CE certificate.

4)Q:What can you do if the machine broken?

A:Our machine's warranty period is 18months,if the broken parts can't repair

we can send the new parts replace the broken parts free,but you need pay the express cost yourself if after warranty period

we can through negotiation for to solve the problems,and we supply the technical support for the whole life of the equipment.

5) Q:Can you be responsible for transport?

A:Yes,please tell me the destination port or address we have rich experience in transport.

6) Q:Can you supply the raw materials?

A:Yes,we can supply the galvanized steel coil,galvalume steel coil,color steel coil,and aluminum coil

Product Categories : Sandwich Panel Roll Forming Machine