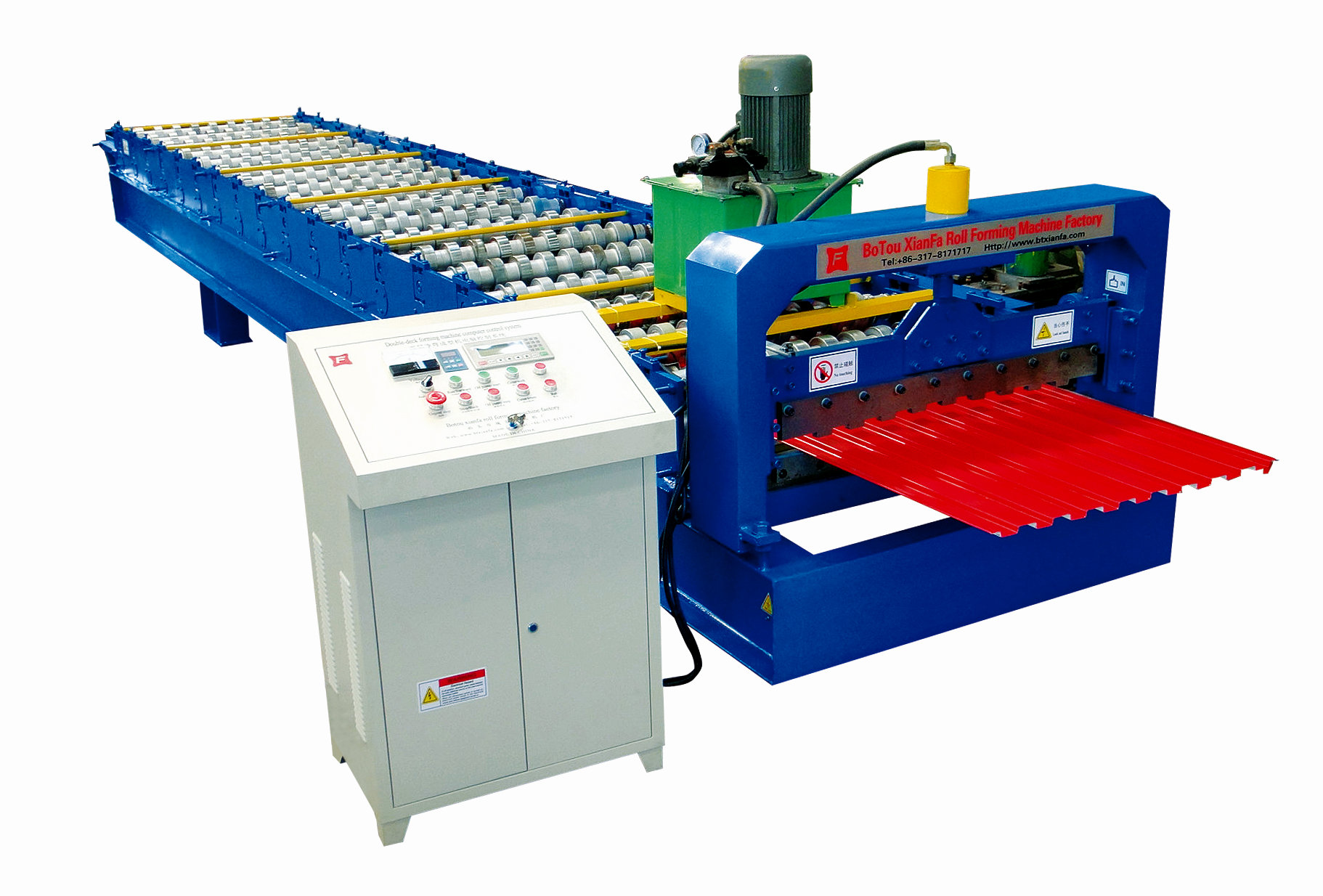

Shutter Door Roll Forming Machine

The shutter door machine has many type of design. The austrilia type use wide raw material width, and easy to make the door. The small type of shutter door strip has nice appearance, and durable product. Besides, there are some other type of shutter door machine, like anti-wind shutter door machine and fire proof shutter door machine. The fire proof shutter door machine has the steel frame with EPS inside.

TECHNICAL SPECIFICATION

(1) 5 tons hydraulic un-coiler:

Hydraulic motor drives. One single-head structure. It has a pressing arm to prevent the coil loose.

Electric uncoiling, hydraulic motor tenses the coil inner.

The max. coil inner-diameter is 508mm.

The max. coil outter-diameter is 1200mm.

The max. width of coil is 1250mm.

The max. capacity is 5 tons.

(2) Roll-Forming M/C:

Welded steel structure base, chains transmit, motor drives it. The machine include the filming device .

The roller is designed by Germany software COPRA, and has FEA analysis, which can promise the product precision.

Material of Roller: 45#, with hard chrome coated, polishing,

Voltage:380V/50Hz

(3) Hydraulic pressing/ Cutting:

Stop to press, Stop to cut, Post cut .Cutting tool material: Cr12, pressing tool material:40Cr.

Tolerance of the cutting length ±2mm.

(4) Product Rack

It is 2 parts, 6 meters total.

Un-powered.

(5) Hydraulic System:

It offers power for the cutter.

(6) Electrical System:

It uses Siemens PLC system to control the whole line. It can measure and cut the length automatically. Frequency adjusts the speed and it has the self-control speed function.

Human-machine screen, touch screen control. The length can be set in touch screen freely and operation is simple.

The surround connecting wires adopts aviation socket or fast-speed plug.

(7) Safety barrier system

Keep the workers safe when working.