Model No.: 25-210-1050

Brand: XF

Type: Automatic

Raw Material Thickness: 0.3-0.6mm

Factory History: 20 Years

Speed Of Production: 0-2m/min

Name: Sheet Roof Roll Forming Machine

Machine Type: Step Tile Roll Forming Machine

Packaging: Main machine is nude,the computer control box is packed by wooden carton box.

Productivity: 30set

Transportation: Ocean

Place of Origin: Botou City, China

Supply Ability: 30

Certificate: CE/ISO

Payment Type: L/C,T/T,cash

Incoterm: FOB,CFR,CIF

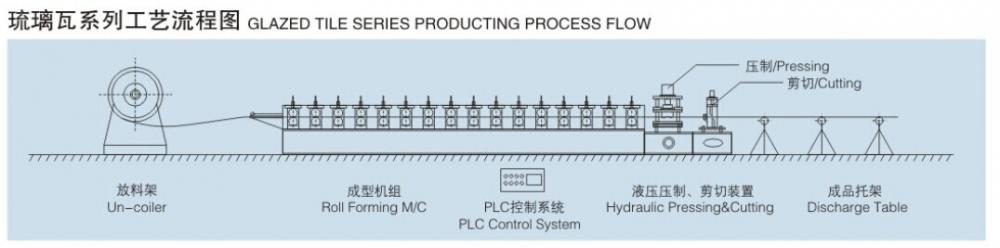

Industrial Process And Component Specification

Corrugated Sheet Metal Roofing Roll Forming Machine

Component Specification

1. Manual Uncoiler:

Usage: It is used to support the steel coil and uncoil it in a turnable way. The steel coil is uncoiled by hand.

Loading capacity: 5T

Inner diameter: 500-508mm

2. Feeding Table:

Put the raw material (steel plate) through the beach to manufacture and process, it can guarantee that the products are neat. Parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron.

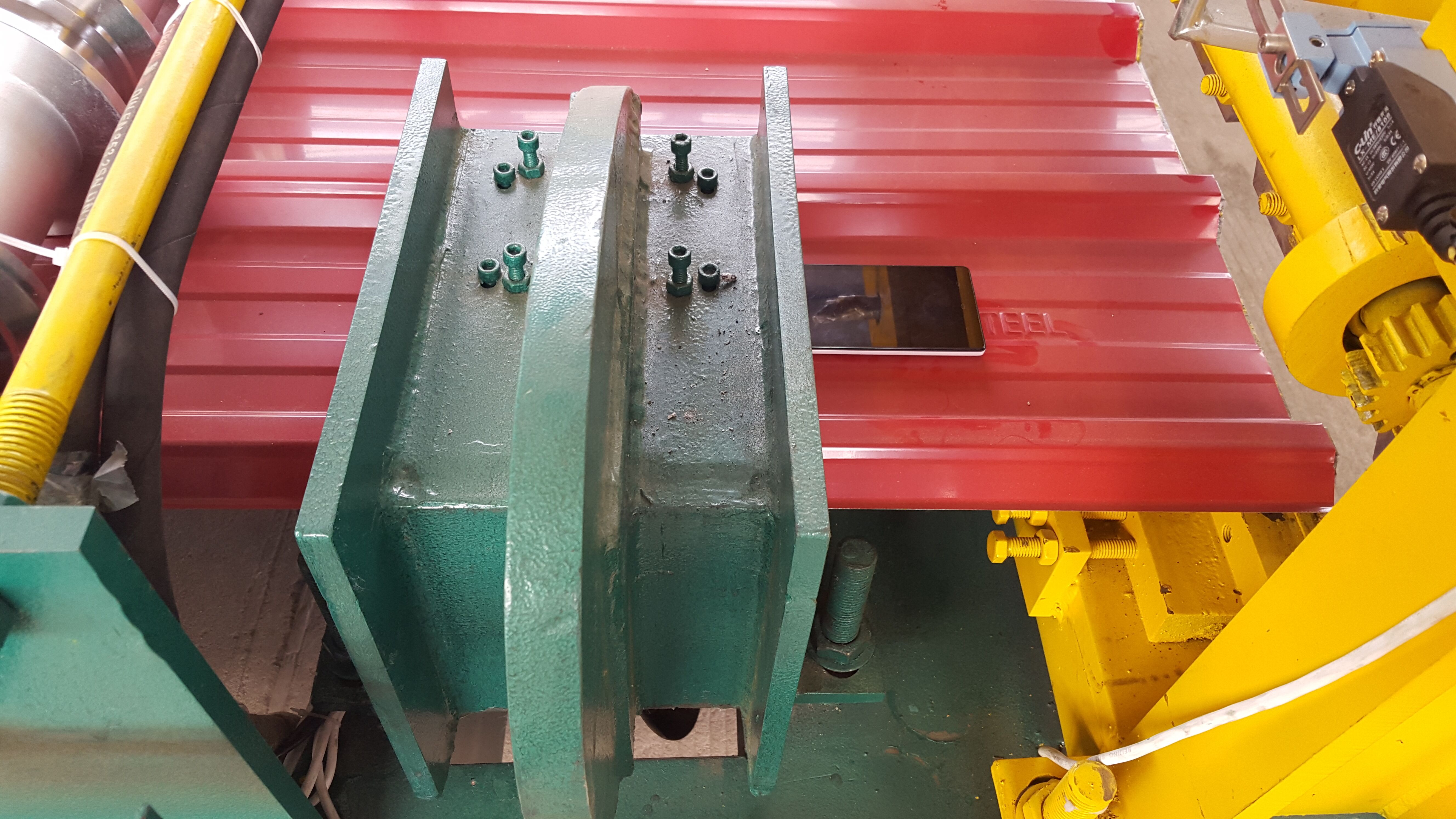

3. Main Roll Forming Machine:

Material of rollers: 45# steel, roller surfaces polishing, hard plating. The polished surface and the heat treatment towards the molds also can keep the molding. Plate surface smooth and not easy to be marked when it is being stamped

4. Hydraulic System:

Hydraulic oil:40#.

Hydraulic oil into the hydraulic oil tank, the pump drives the cutter machine to begin the cutting job.

5. Shearing Mechanism: It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products. Material of blades: Cr12, quenching treatment.

6. Computer Control Cabinet: The target piece`s length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one. The system is easy to operate and use. Plc: EURA

Packaging & Shipping

1. We have professional technicians for loading

Guaranteed the goods load into container without any damage.

2. Transportation : Machines need one 40 feet container to hold

Our Services

1. Warranty

One year,and we will provide technical support for wholelife of the equipment.

2. Installation And Charge

Purchaser pays all charges during period of install to overseas,

(include charges of food,lodging and round trip air tickets ,etc.)

Moreover,pay subsidy 60USD/day until Installation finished.

Botou Xianfa Roll Forming Machine Factory

Recently,our products have been exported to more than 80 countries and regions over the world

and maintained good cooperative relations with customers

Company Certification

Contact Information

Product Categories : Roll Forming Machine Series > Trapezoidal Roll Forming Machine