Model No.: XF1025 Vermiculite Tile Forming Machine

Brand: XF

Certification: ISO

Condition: New

Customized: Customized

Automatic Grade: Automatic

Structure: Other

Transmission Method: Hydraulic Pressure

Thickness Of The Plate: 0.3-0.7mm

PLC Brand: Japanese Brand

Machine Name: Vermiculite Tile Forming Machine

Name: Vermiculite Tile Machine

Machine Type: Roofing Tile Vermiculite Tile Forming Machine

Voltage: According To Customer Requirement

Packaging: We have professional technicians for loading Guaranteed the goods load into container without any damage.

Productivity: 30set

Transportation: Ocean,Land

Place of Origin: Botou City China

Supply Ability: 30

Certificate: CE/ISO

HS Code: 8455221000

Port: Tianjin New Port

Payment Type: L/C,T/T,D/P,Western Union

Incoterm: FOB,CFR,CIF

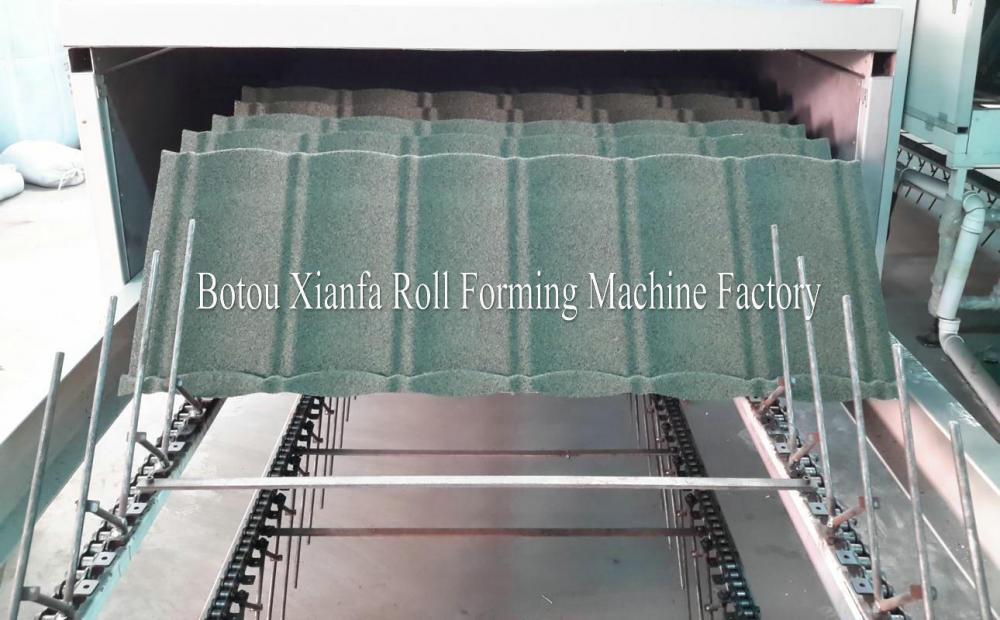

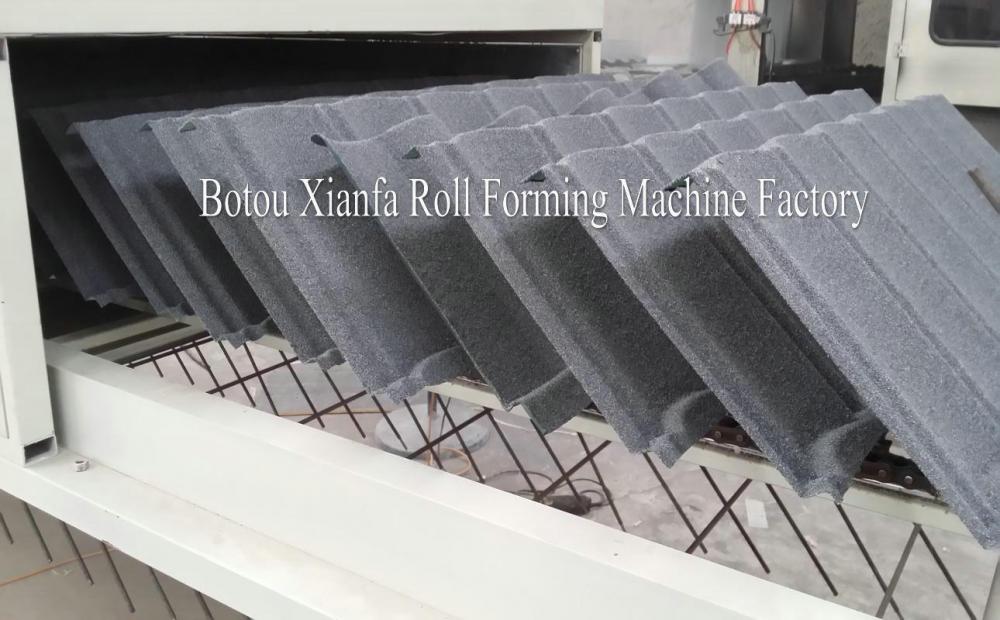

XF Galvanized Steel Sheet Vermiculite Tile Forming Machine

Galvanized Steel Sheet Vermiculite Machine,XF Vermiculite Tile Forming Machine,African style Vermiculite Tile Forming Machine

XF-Vermiculite Tile Forming Machine ( Sand Blast Part )

Automatic Bottom Glue Spraying Equipment

| Closed automatic spraying glue system |

| Outside Dimension:4000*1350*850mm(L*W*H) |

| Structure:Channel steel ,welded |

| Conveying device:Reciprocating chain conveys |

| Adsorption of dust removal equipment:1 set |

| Air compressor: 1 set, 7.5kw, air output is 1m³/min |

| D46 high-pressure airless spraying system 1 set (German technology) |

| Automatic high-pressure airless spraying gun: 1 set (Japanese technology) |

| High-pressure airless manual spraying gun:1 set(Japanese technology) |

| Standard 15M German import high-pressure airless feed tube and it can support the maximum pressure is 20Mpa |

| 100L stainless charging basket 1 piece |

Automatic Sandblasting Room

| Outside Dimension :3000*1850*700mm(L*W*H) |

| Structure:Channel steel ,angle steel ,welded |

| Transmission:With glue spraying equipment compound chain transmit |

| Conveying device:Compound chain transmit |

| Air compressor: 1 set, 18.5kw, air output is 3m³/min |

| High-pressure sand suction system: 1 set, sand suction is 1T/hour |

| Sand hopper: 1 set, dimension:550*600*500 |

| Automatic shaking sand system: one cylinder, the motor with 0.75kw, control: PLC |

First Drying Room

| Outside Dimension:4000*1350*850mm(L*W*H) |

| Structure:Channel steel ,welded |

| Conveying device:Reciprocating chain conveys |

| Adsorption of dust removal equipment:1 set |

| Air compressor: 1 set, 7.5kw, air output is 1m³/min |

| D46 high-pressure airless spraying system 1 set |

| Automatic high-pressure airless spraying gun: 1 set |

| High-pressure airless manual spraying gun:1 set |

| Standard 15M German import high-pressure airless feed tube and it can support the maximum pressure is 20Mpa |

| 100L stainless charging basket 1 piece |

Automatic Surface Glue Spraying Equipment

| Outside Dimension :30000*850*700mm(L*W*H) |

| Structure:carbon steel welded |

| Frame insulation wall: 30 meters` long, 1mm carbon steel plate bending forming filled with cotton insulation |

| Automatic temperature controller:2 sets,Range of adjustable temperature:0-160° |

| Infrared fluorescent tube:50 pieces |

| Conveying device: Reciprocating chain conveys 30m |

| Cooling device:1 set |

| Total equipment matches total control station 2 sets (Control system) |

| Productivity:3-6m/min Calculate as 1.2m per piece,eight hours,produce 1500pcs every day |

| Whole machine power:130kw |

Second Drying Room Equipment Component

| Spare parts: Infrared fluorescent tube: 10 pieces, nozzle:2 pieces |

Production Sample

1.We have a professional design team

2.Can also design and manufacture according to customer's requirement.

Payment method

Method 1:30% deposit by T/T in advance and 70% balance after inspection confirmation before shipment

Method 2:L/C is also acceptable.

Installation, Commissioning, Test and Training

1. The engineers from the Seller shall supervise the installation on site and fulfill the commissioning.

They should start off within 10 days after they get the information from the Buyer.

2. The Buyer shall pay for the international air tickets and the local, such as board and lodging, daily transportation, communication,Insurance,

etc. The Buyer shall pay USD 100 /day /person to the Seller for the commissioning.

3. The Buyer shall prepare an interpreter for better communication between the two sides.

Looking for ideal Roofing Roll Forming Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative.

All the Roofing Roll Forming Machine are quality guaranteed. We are China Origin Factory of Roll Forming Machine

If you have any question, please feel free to contact us.

Product Categories :Manufacturing & Processing Machinery > Building Material Making Machinery > Tile Making Machine>

Vermiculite Tile Forming Machine

Product Categories : Vermiculite Tile Roll Forming Machine